By CASEY NEILL

ELEPHANTS at the Melbourne Zoo, sports fans at the MCG and diners on Crown’s promenade all have a Springvale business to thank for keeping them warm.

Bob and Marie Reynolds established Thermofilm Australia 26 years ago to produce indoor and outdoor electric heating products utilising a thin film carbon-based heating element.

The Heatstrip has been on the market about 20 years, is exported to New Zealand, Europe, USA, Canada and Asia, and last year won the Australian Business Award for Product Value.

Thermofilm last week won the Victorian Manufacturing Hall of Fame Small Manufacturer of the Year award.

Operations manager Ben Murphy said the Heatstrip’s design, quality and reliability had made it a success.

“And they don’t glow and that’s what’s unique,” he said.

The product was used in the elephant enclosure at Melbourne Zoo, the MCG Great Southern Stand refurbishment, and in former cricketer Shane Warne’s lounge bar Club 23 at Crown Casino.

The venue features an elaborate balcony overlooking the city skyline with Heatstrip heaters. Their slimline, sleek, unobtrusive design blends seamlessly with the balcony and the suspended ceiling mount does not obstruct any skyline views.

Mr Murphy regularly – and proudly – spots the product at cafes and other venues across Melbourne and its suburbs.

But Heatstrip isn’t all Thermofilm has to offer.

It’s been producing heated propagation trays to keep soil warm for about 15 years, and among its best-selling products are accessories like poles to mount their heaters and a Heatstrip controller that can automatically turn off the device to save power.

Mr Murphy said staff tested each heater three times and each product was serial numbered in case of failure.

“Safety is absolutely paramount,” he said.

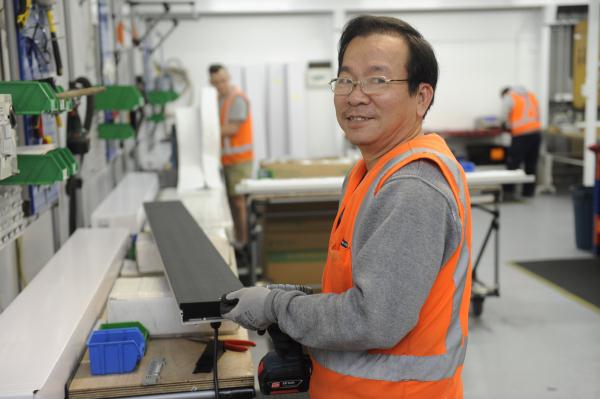

About seven people work on the Springvale production line and Thermofilm employs about 18 staff in total.

Mr Murphy, an engineer by trade, has worked there for the past four years and is among five managers that co-own the business.

“We don’t bring out a lot of products. But they fill the need of the customer,” he said.

“We are growing and it’s slow and incremental. It’s sustainable.”

Thermofilm is facing competition from all over the world.

“Not just the guy down the road,” he said.

“The Germans and Chinese are trying to copy us at the moment and they can’t do it.

“I don’t think about it as pressure. You compete wherever you are for the best solution possible and bring it to market.”

Mr Murphy said constant innovation was the key to Thermofilm’s success – and not being afraid to fail.

“With innovation comes failures. People that are following you, they hit those failures as well,” he said.

“Some products just don’t make it. It’s a constant process.”

Quality is another way Thermofilm sets its products apart from cheaper imports.

“Nothing goes out that’s not 100 per cent,” he said.

“Building relationships with suppliers is the key. They know the quality expectations of the customers.

“They’re willing to pay more for a quality product that lasts for years.”

And the international market is willing to pay for it, too.

In the past two months, about half of Thermofilm’s products have been sent overseas.

“It’s very seasonal. Some months it’s about 15 per cent,” Mr Murphy said.

“It probably averages about 30 per cent.”

And while Thermofilm sells overseas, it’s determined to buy local to support the region.

“The response time is a lot quicker and if something goes wrong they’re just around the corner,” Mr Murphy said.